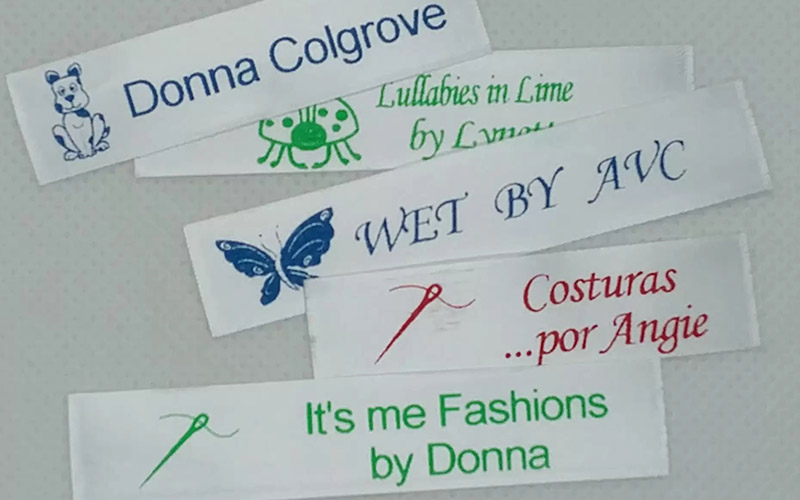

When it comes to branding garments, the small details often make the biggest impact. Woven labels play a crucial role in not only serving as a marker of identity but also in enhancing brand recognition. At Woven Labels Direct, we understand the importance of finding the perfect label to meet your specific needs. This article delves into the key considerations you should make when choosing between sew-on, iron-on, and stick-on labels. Explore our range of name labels, craft and couture labels, and custom woven labels to find the best fit for your project.

On This Article:

- Understanding Iron-On, Sew-In Woven and Stick-On Labels

- Iron-On Labels

- Sew-On Labels

- Stick-On Labels

- Factors to Consider When Choosing Between Iron-On and Sew-In Woven Labels

- Where to go from here?

Understanding Iron-On, Sew-In Woven and Stick-On Labels

Overview of Label Types

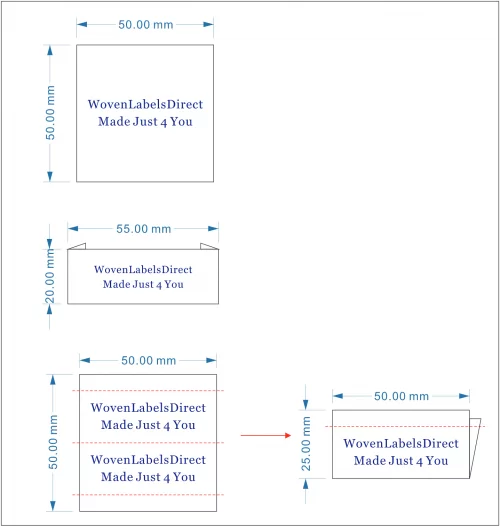

Labels are more than just fabric pieces; they are a testament to a brand’s quality and attention to detail. The choice between iron-on, sew-in, and stick-on labels often depends on the application process and the durability required.

Application Process

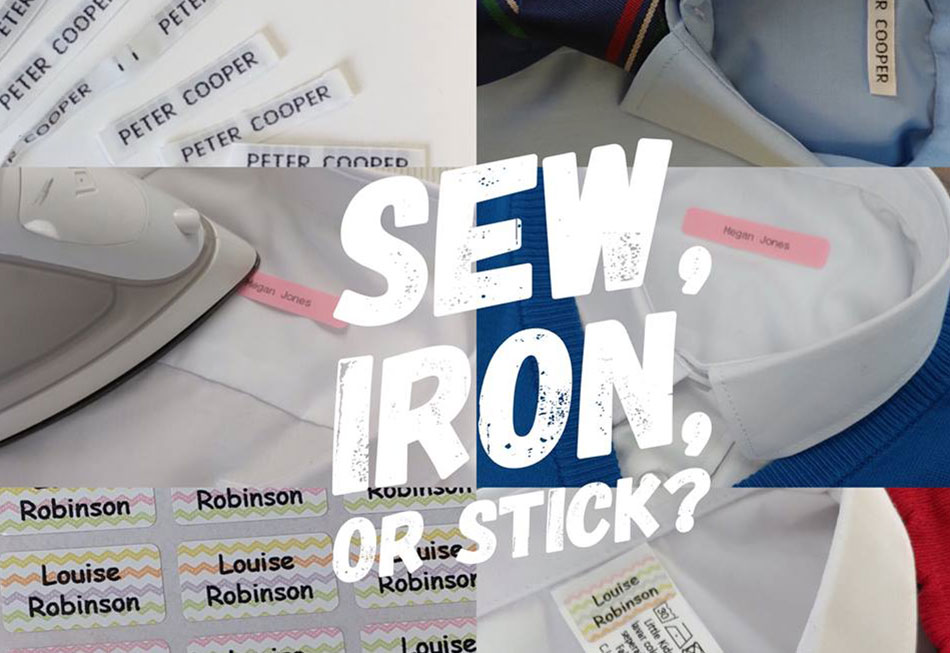

Each label type comes with its own set of application methods. Iron-on labels, for instance, require a heat press or iron to attach, making them convenient yet dependent on heat-sensitive materials. Sew-on labels offer a more permanent solution, demanding sewing skills for attachment. Stick-on labels provide a quick fix but are generally suitable only for temporary use.

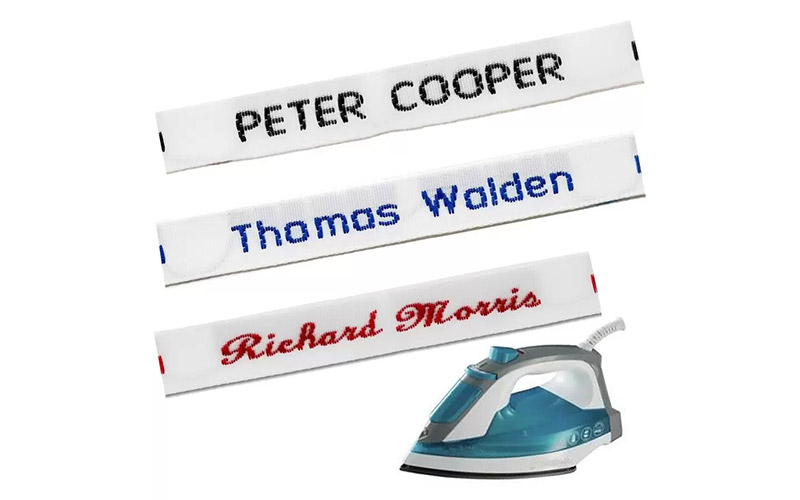

1. Iron-On Labels

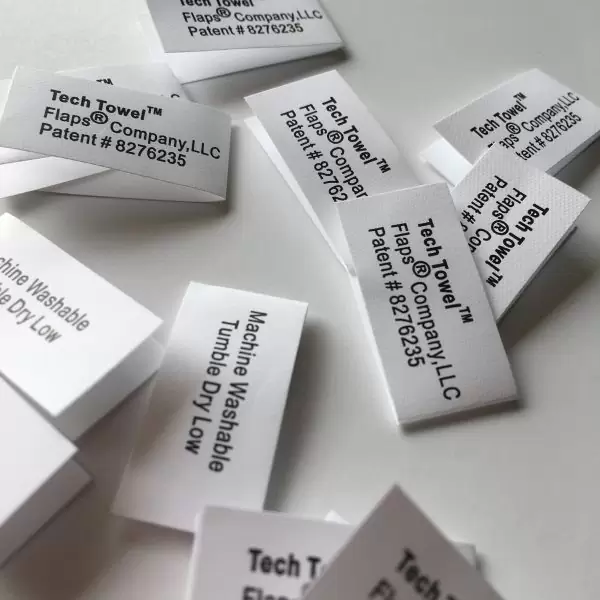

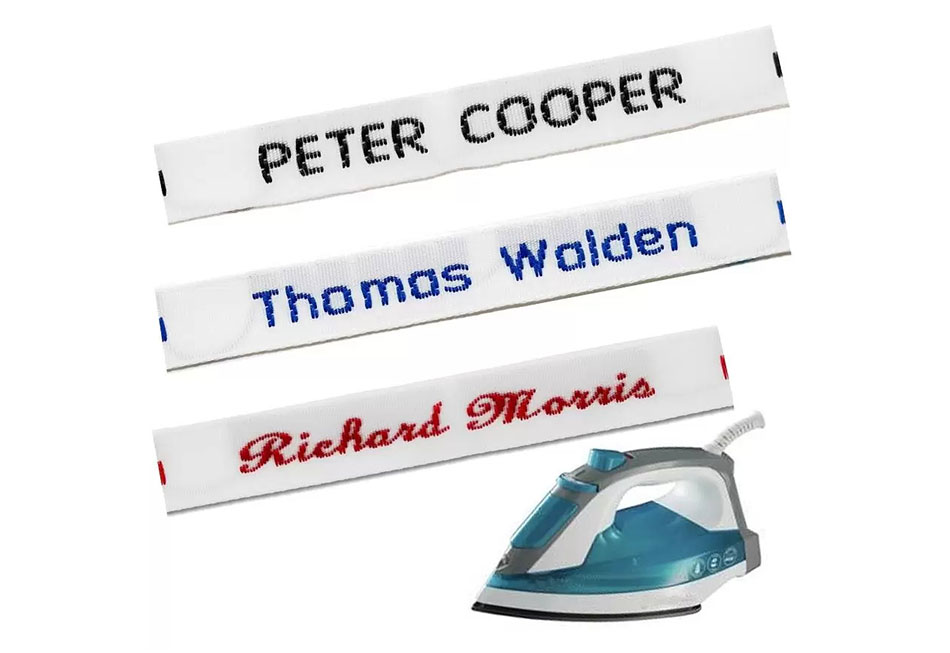

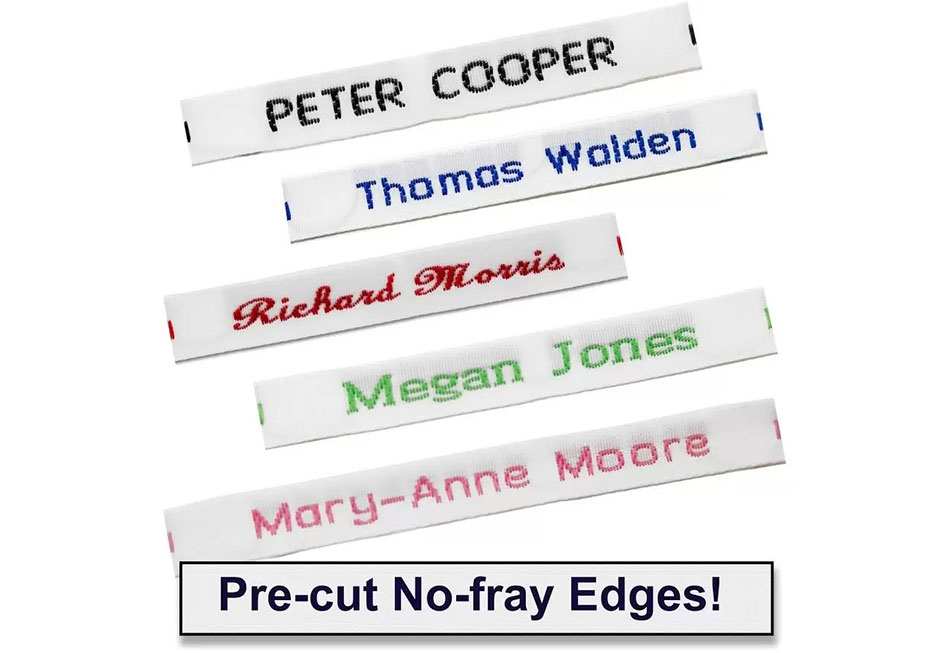

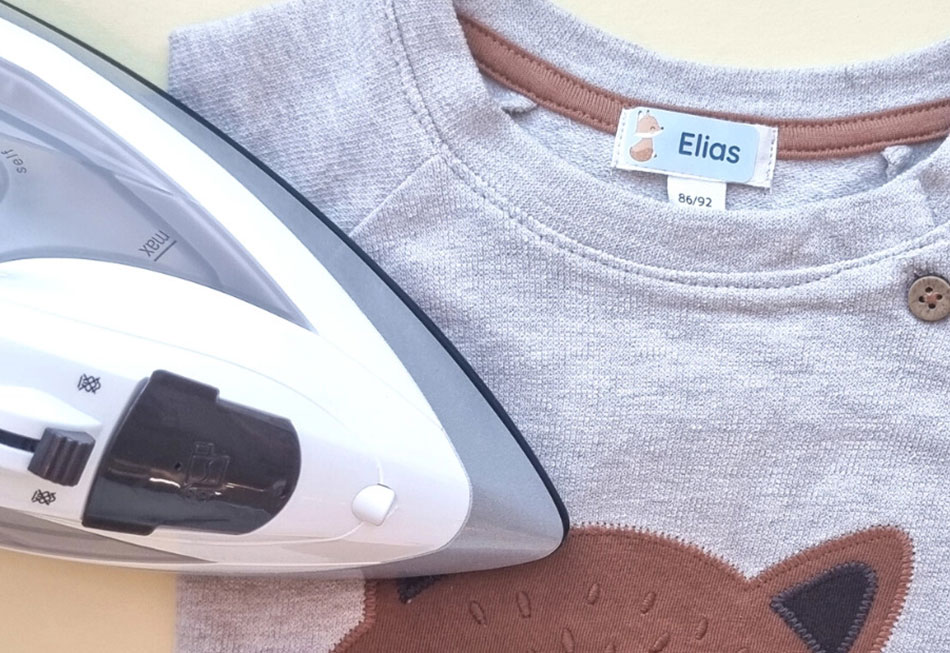

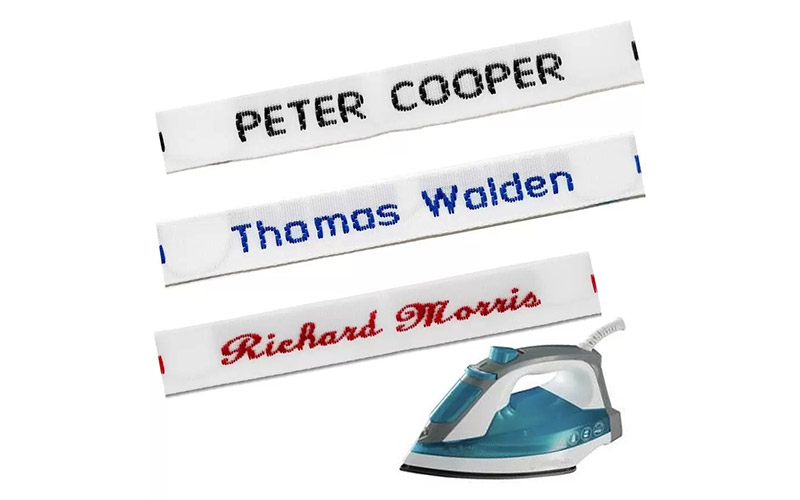

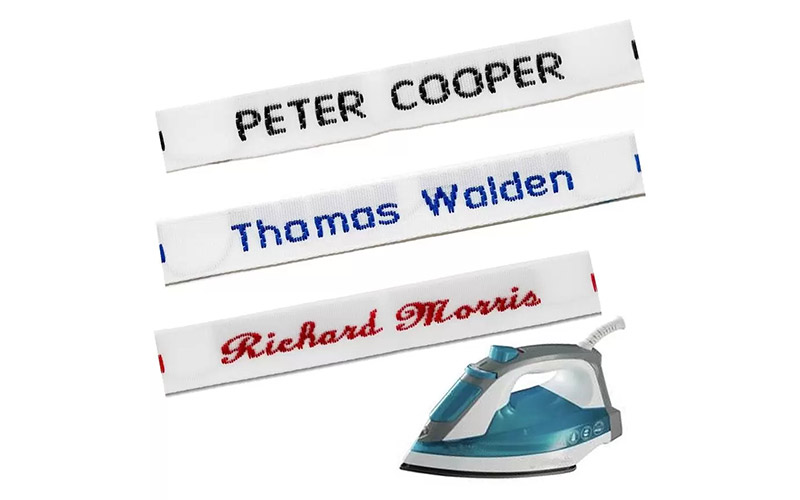

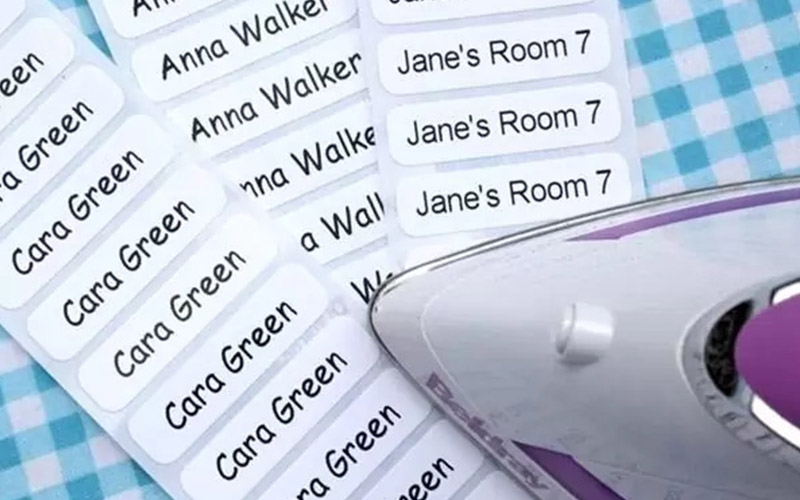

Explore the ease and efficiency of our woven iron-on and satin iron-on labels. These labels are perfect for quick applications, using a heat-activated adhesive backing that securely attaches to garments.

Convenience and Time-Saving

The main draw of iron-on labels is their ease of use. Simply position the label, apply heat, and you’re done. This process saves significant time, especially for large batches of garments.

if you do want to label smaller items, like handkerchiefs, socks, etc, you can buy a set of Iron-On labels to make sure all items are labelled well. – Labelbubble

Requirement of Iron or Heat Press Machine

Although iron-on labels are convenient, they do require access to an iron or a heat press machine, which may not be readily available in all settings.

Versatility

Iron-on labels are versatile, suitable for a wide range of fabrics and items beyond clothing, such as bags and accessories.

Back in the day, parents and grandparents would sew on labels to keep track of clothes, lunchboxes, and water bottles. But the days of time-consuming sewing is long gone. Technology has brought us other options like stick-on and iron-on tags. – Labels4school

Durability

When applied correctly, iron-on labels are durable and can withstand multiple washes, though they are generally less durable than sew-on labels.

Heat Sensitivity

One limitation is their heat sensitivity; not all fabrics can tolerate the high temperatures needed to apply these labels.

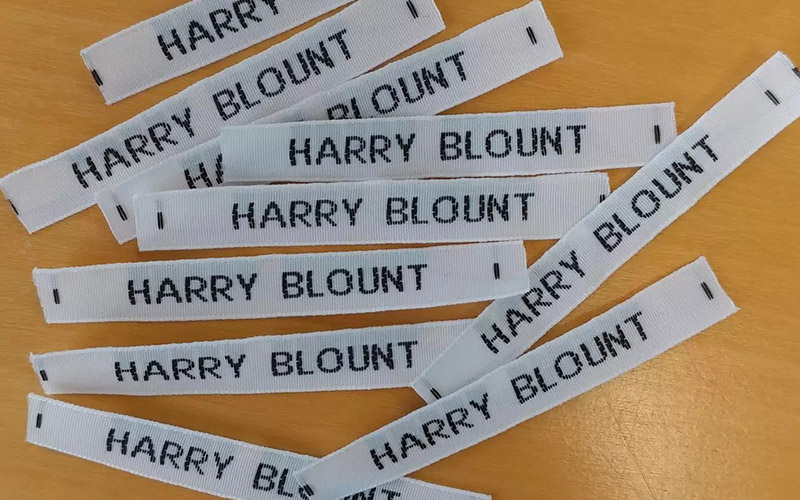

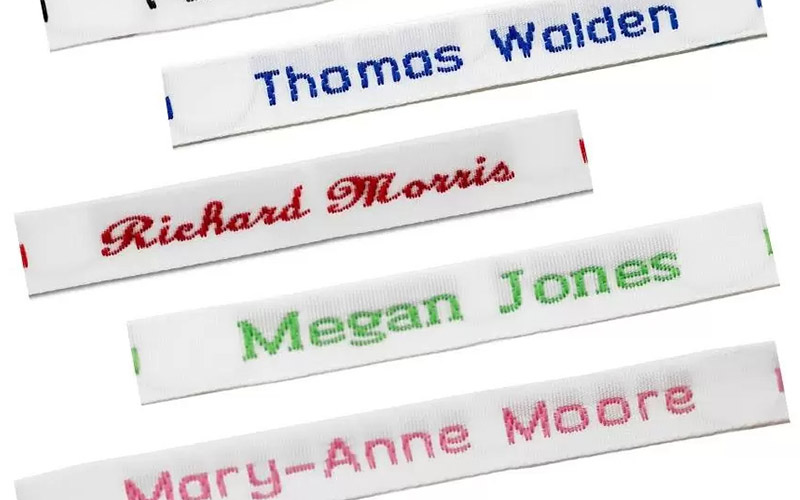

2. Sew-On Labels

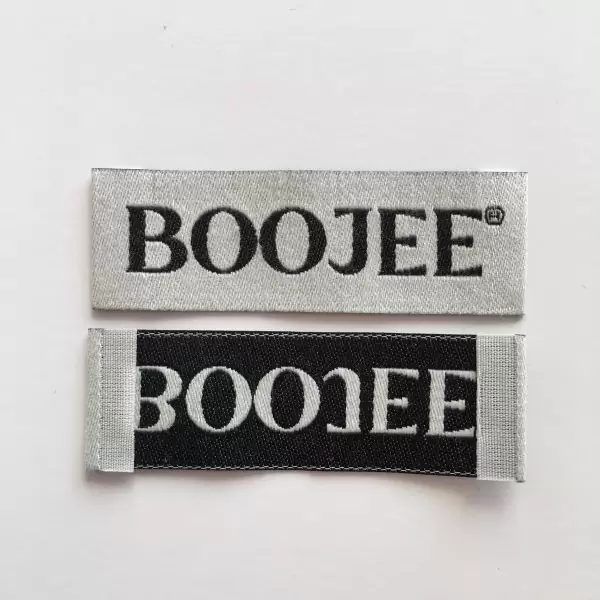

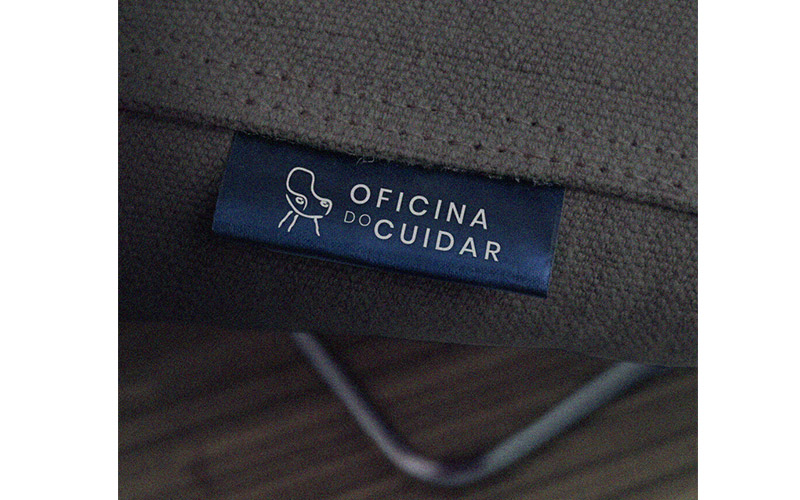

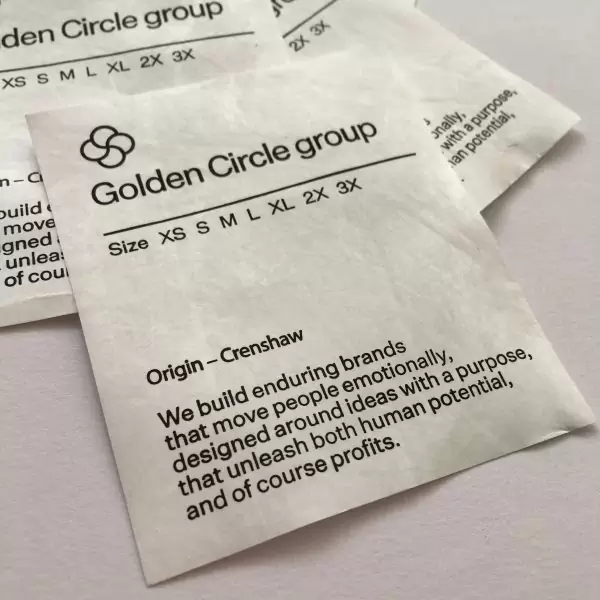

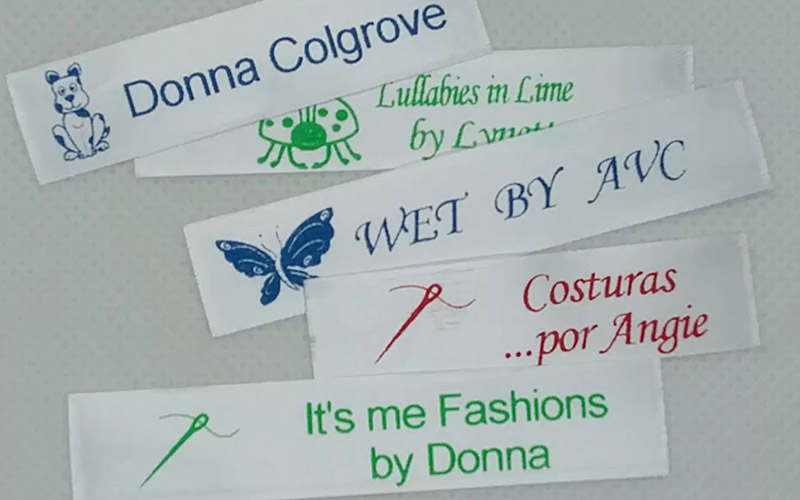

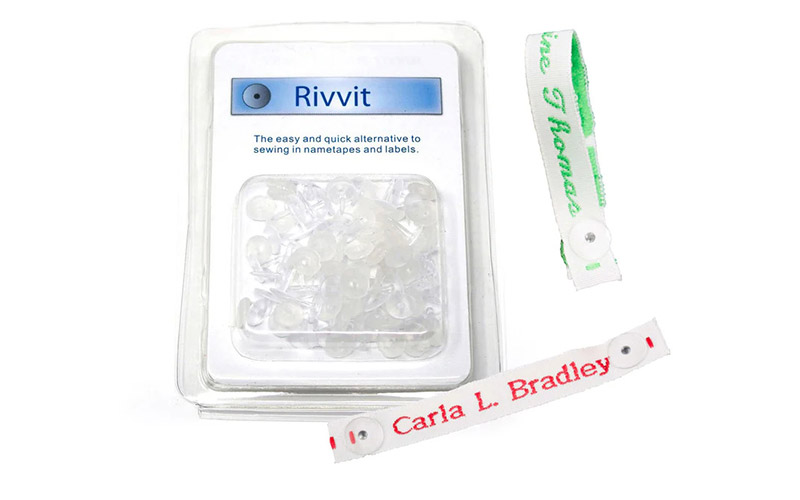

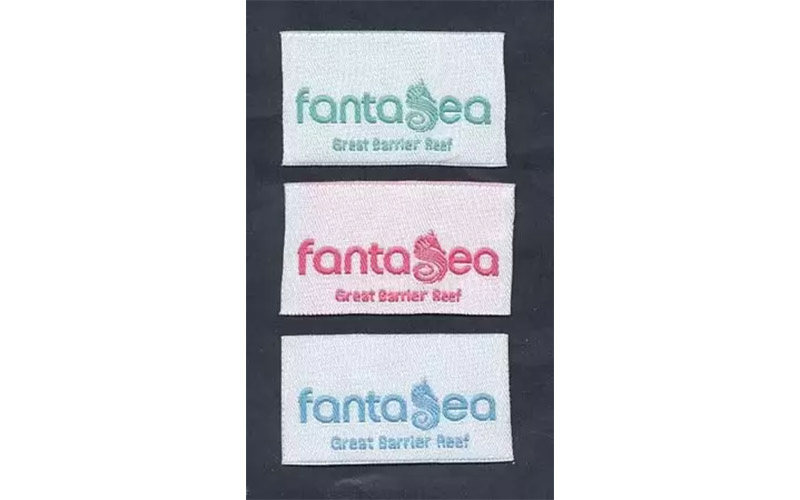

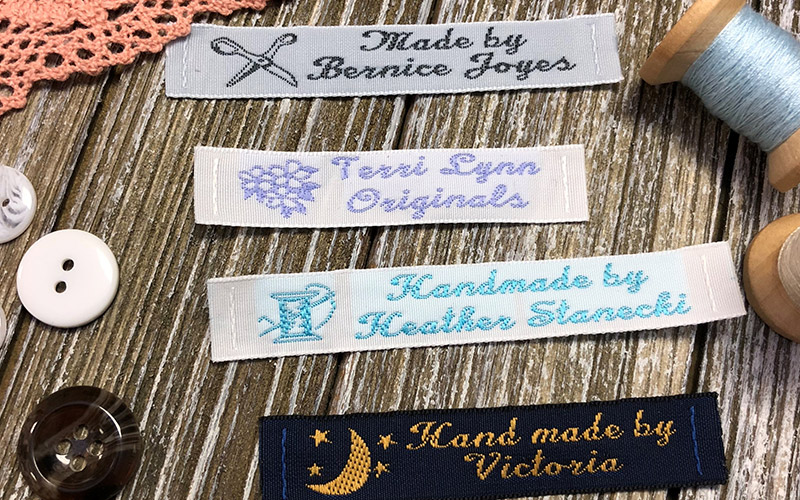

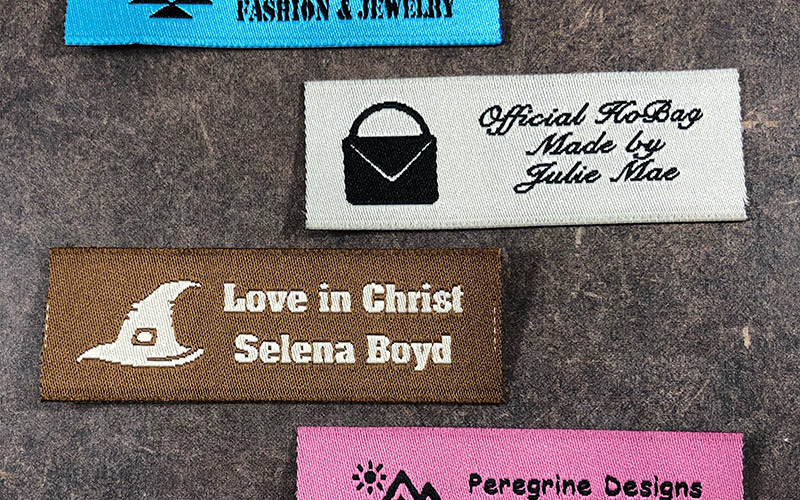

Sew-on labels are renowned for their durability and longevity. They offer a professional appearance and a variety of customisation options, making them a favorite for high-quality garments.

Advantages

The sew-on method provides a secure attachment that is likely to outlast the garment itself, ensuring the label remains intact for the life of the item.

Stick on labels are easier to use and don’t require any tools, and you aren’t sacrificing any stickiness or quality. And the quick time it takes to apply vs. iron-on labels is a no brainer. – Leeleebles

Durability and Longevity

These labels are incredibly durable, capable of withstanding harsh washing and drying conditions without peeling or fading.

Professional Appearance

Sew-on labels offer a high-end, professional look that is often preferred for designer garments and luxury items.

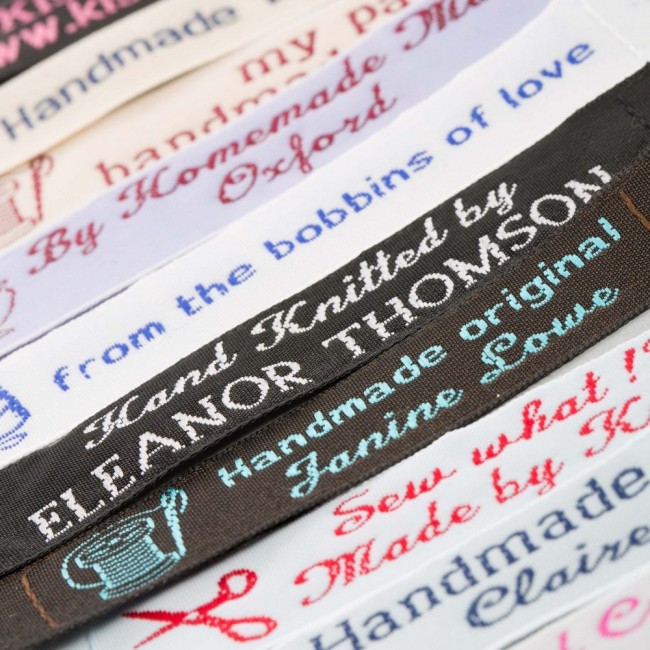

Customisation Options

With sew-on labels, the options for customization are nearly limitless, allowing for unique fonts, logos, and intricate designs.

Permanent Attachment

Once sewn, these labels are permanently attached, ensuring they do not come off unless physically removed.

Disadvantages of Sew-On Labels

- Time-Consuming: Sewing labels onto garments is more labor-intensive than ironing them on.

- Sewing Skills Required: This method requires basic sewing skills, which may be a barrier for some users.

- Limitations: They may not be suitable for all types of fabrics, particularly those that are too delicate to withstand sewing.

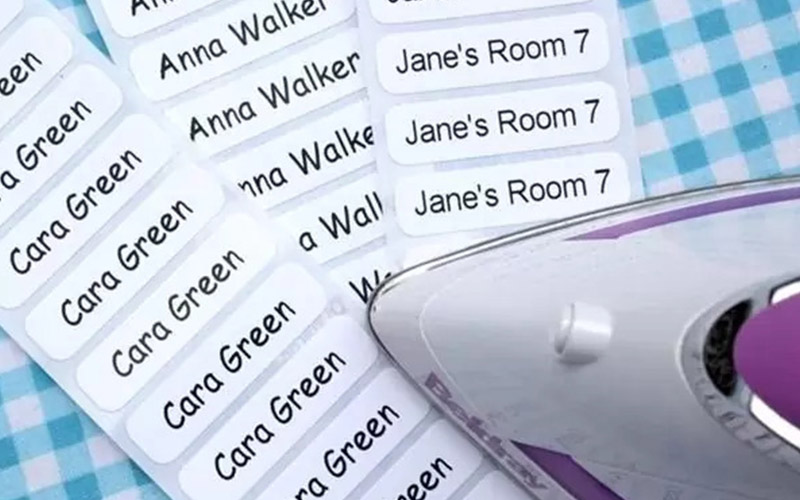

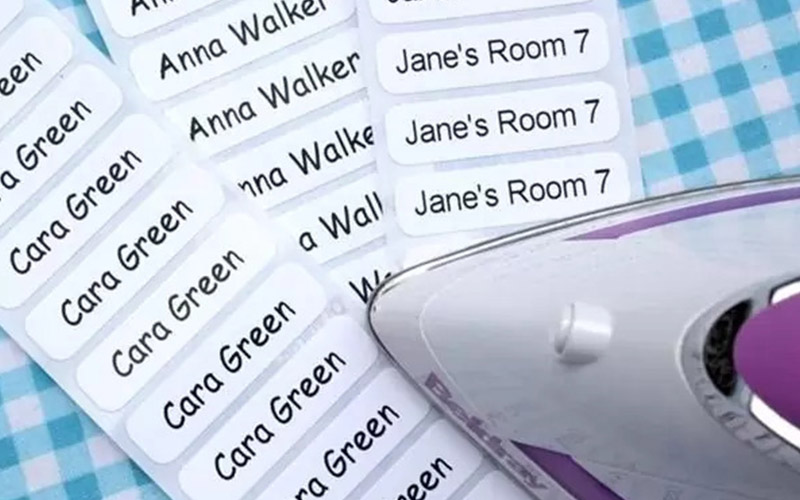

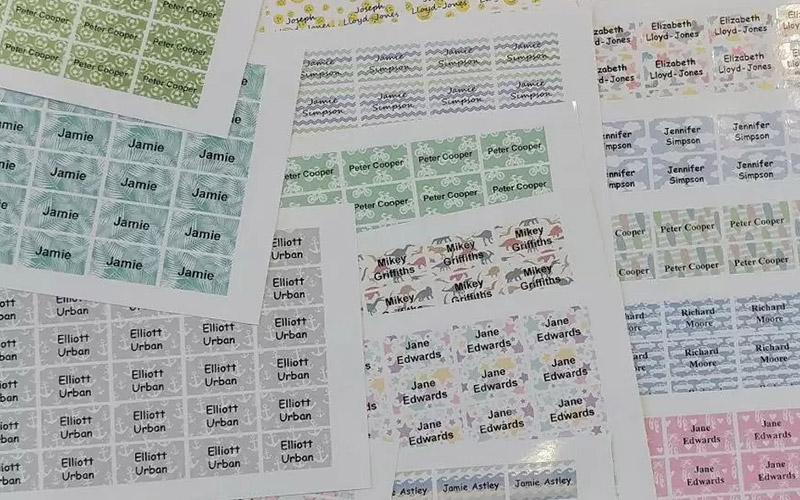

3. Stick-On Labels

Our super sticky name labels are ideal for non-clothing items. They are microwave and dishwasher safe, designed for items like lunchboxes and water bottles, and can last up to 20 washes on clothing.

For Temporary Use Only

Stick-on labels are primarily for temporary applications. They are easy to apply and remove, making them perfect for short-term use.

With so many easier and cheaper alternatives on the market today, you might be forgiven for wondering why anyone would choose sew-in name labels over iron-on labels or stickers. But the answer is quite simple: people tend to stick with what they know. – Mynametags

Bright Colours and Images

These labels often come in bright colors with the option to include images, helping to easily identify personal items.

Factors to Consider When Choosing Between Iron-On and Sew-In Woven Labels

When deciding between iron-on and sew-on labels, consider the following:

- Garment Type and Fabric Considerations: Some fabrics may be better suited to one type of label over another.

- Durability Requirements: Consider how long the label needs to last and under what conditions it will be used.

- Branding and Aesthetics: The choice of label can affect the overall look of the garment and thus the brand image.

- Application Time and Resources: Evaluate the resources available for applying the labels.

- Reusability and Flexibility: Determine if the label needs to be removable or adjustable.

- Cost Considerations: Factor in the cost differences between sew-on and iron-on options.

Where to go from here?

Choosing the right type of label for your garments involves understanding the unique characteristics, pros and cons of each type, and of course, also preference. At the end of the day, as long as you know what’s involved with each type, and their best application, you’re good to go!